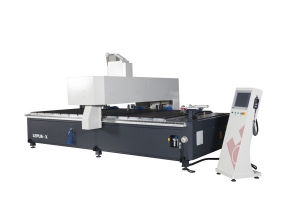

LEPUS - X

CNC Controlled Aluminum and Composite Panel Processing Machine - 4 m (3 Axis)

FEATURES

Used for v-channel opening, processing and sizing operations of aluminum and composite panels and plates. Aluminum profiles can be processed with optional equipment.

- Processible material types/classes; aluminum plate, aluminum composite panel, laminated composite, wooden laminated composite, various plastic plates, aluminum industrial or semi-industrial plates

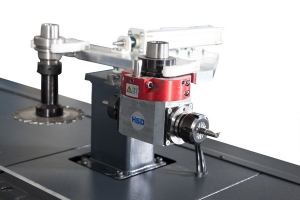

- Automatic magazine for 8 tools

- Ability to process wooden and plastic plates by replacement of milling cutter

- Smart CAM post processing

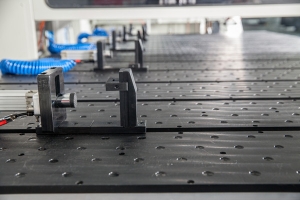

- Vacuuming in independent sections

- Automatic tool length measurement

- External dust vacuuming system

- Automatic, pneumatic alignment system

- Industrial PC with Windows based touchscreen and easy to use practical interface

- Remote access

- Data transfer over remote network connection, Ethernet and USB

- Special vacuum circuit designed for local vacuuming and automatic zoning

- Automatic lubrication in processing area

- Automatic zoning with the ability to routinely focus vacuum on processing area thanks to the special software

- Pneumatic clamps for optional profile processing feature

- Ability to disable dust vacuuming system when pneumatic clamping system is activated

- Dust vacuuming system impact control with large tool procedure

- Processing at -90°, 0, +90° fixed angles with profile processing feature and recommended special tools, and end milling with a saw blade with maximum 150 mm diameter

- Ability to process 5 surfaces (top, sides, heads) of the profile

STANDARD EQUIPMENTS

2D CAD CAM

Cutter (2 pcs 4 mm cutter, 2 pcs V channel cutter)

Vacuum cleaner for chips

OPTIONAL EQUIPMENTS

Special cutter tools

Optional length

Profile processing feature