ALT EF65 Unitized curtain wall system

ALT EF65 Unitized curtain wall system

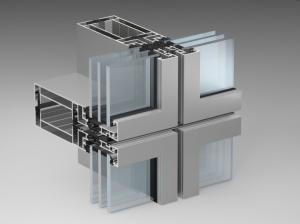

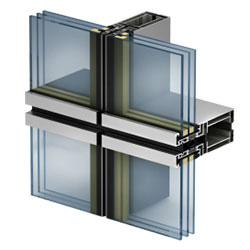

Unitized curtain wall system ALT EF65 was designed to create curtain walls glazing using ready modules (elements), which were assembled in a workshop beforehand. This way of assembling allows to omit the process of scaffold installation and makes high-rise construction a lot easier.

The main components of this system are frame profiles and transom bars which form units. Infill units in such constructions are fixed with the help of glazing beads and wedge gaskets. Gasket kit is used for joining and caulking of the units together.

ALT EF 65 system allows to fully assemble in a workshop and easily install on the building sight large panels and glazed units (including installing of such elements as stationary window frames, ventilation systems and special below-window wall panels).

Unitized curtain walls are assembled in the following order

First step:

Units from aluminum profiles and IGUs (glass, solid infill units) are assembled on a plant.

Second step:

Land surveying of the building and bearing structures installation on a slab.

Third step:

Produced units are packed and shipped to the building sight in containers, where they are hanged on the bearers fixed to the slaps.

Unitized curtain wall advantages

Due to high-level of workshop assembly unitized curtain walls have advantages over mullion-transom facade in mounting terms and assembled structure’s quality, meaning:

Variants of build in structures of ALT EF65 unitized curtain wall system

It is possible to install integrated ALT F50 windows with outward opening into ALT EF 65 system. In case of glazing of low-rise buildings with the help of unitized curtain wall system EF65 it is possible to use ALT W72 windows with inward opening.

Integrated window with hidden sash

Integrated window with hidden sash There are no visible differences between this construction and dumb parts of the facade. That’s why this sash can be used in any type of facades.

Integrated window with visible IGU fastening

Standard glazing is used in this window. It is fixed by a pressing bar with 40 mm visible width. It is advised to use this variant in facades with infill units fastened by glazing beads.

ALT W62 and ALT W72 windows with different types of opening

These constructions are used for inward opening and in case it is needed to visually emphasize opening elements against the whole facade.

ALT EF65 system particular qualities

Junction of frames of different sizes

Possibility of junction of frames of different sizes allows to optimize the choice of materials in central wings of the building and to choose a matching profile in loaded (corner) facade areas.

Multi-chamber frame profiles

During workshop assembly of the units frame profiles cutting is performed under the angle of 45° as in case of frames assembly process. Frame profile has three closed chambers. Multi-chamber frame profiles used together with angles assembled with the help of three jetnut elements give additional degree of fixity and durability to the element. Jetnut elements are treated with one- or two-pack glue, during structure assembly, angles fixation is possible with the help of angle-crimping tool or with the help of stub nails.

Two types of transom bars junction

Transom profiles fixation is made with the help of end self-tapping screws. Besides, there is a set of transoms with jetnut elements mounting. The system has a screw and stub nail fastening of a front, middle and back parts of a transom in order to ensure some additional security of T-junction. Compared to alternative systems key feature of ALT EF65 system is the absence of complex profiles’ shaping operations during structure assembly, which minimizes the time of modules’ assembly, reduces labour input, raises end product quality.

Two ways of glazing beads fixation

Modules glazing and panels or window constructions installation is made in a warehouse right at a time of elements’ assembly. Infill units in this system are fixed with the help of glazing beads and wedging gaskets. Glazing beads cutting is done at an angle of 45°, which differs from window-door structures. In order to exclude a spontaneous clicking off of glazing beads during the process of transportation and units’ assembling, and also during the process of building envelope exploitation. There are following methods of fixation provided in ALT EF65 system:

- With the help of end self-tapping screws;

- With the help of EF65.2000 element made from stainless steel.

Several possible variants of angle module realization

Modules (units) can be joined at a random angle depending on the configuration or building fasade. It is possible to rotate the fasade on the angle of 1,5° to the side along the lone of units’ junction in case of standard gasket choice. In the place of fasade rotation at the angle of ±90° it is necessary to use angle modules, which are produced with the help of special angle mullions profiles.

Horizontal profiles chambers completeness

Horizontal profiles chambers completeness in angle modules provides additional level of facade impermeability.

Additional mating element

Using of additional mating element (EF65.1953 pivot and EF65.1954) in corner and two-sectional modules allows to provide equal windload distribution on vertical profiles.

Bearing kit availiability

System mounting elements are used in order to fasten the units to building footing. Bearing kits for units installation on the building are made of steel with zinc covering. This products are complemented with different metalware and provide an easy and secure fastening, adjustment, strain expansion compensation.

High thermal performance

34-mm multi-chamber polyamide thermal breaks of German company Technoform are used in frame and transom profiles. Transom insulating chamber is filled with foamed inserts from low thermal conductivity material. High impermeability level of the construction is reached through the use of four-contour kit of gaskets. All of it allows to raise fasade thermal performance and to reach «frame–frame» thermal transmittance level of Uf=2,25 W/(m²°K) and transom assembly unit is Uf=1,55 W/(m²°K).

High impermeability level of the construction

Air and water permeability requirements for fasade elements structures are connected with the differential pressure between the inside and the outside of the building on big heights and determine the use of multi-contour gasket kit and overlapping principle of gaskets.

Design variants of unitized curtain wall ALT EF65

-

TRADITIONAL FACADE

visible attachment of window assembly with the help of glazing beads

-

SEMI-STRUCTURAL GLAZING «vertical line»

with a vertical profile line on a facade

-

SEMI-STRUCTURAL GLAZING «horizontal line»

with a horizontal profile line on a facade

-

STRUCTURAL GLAZING «vertical line»

all-glass facade without any aluminum profiles outside